Global Specification

Many OEMs provide a solution using proprietary software and controls solutions that lock users in. These solutions also include components and subsystems that may not be in the best interest of the customer, but instead are the highest profit product for the OEM. Fídus Global provides a Global Specification service to provide companies with a baseline of specification to avoid hard to support hardware and avoid proprietary “black box” solutions that limit the ability to support their equipment without involvement from the OEM. This provides your company with the freedom to make changes to your material handling system without costly change orders and long lead time projects with the OEM.

Key Details

Avoid Proprietary Solutions

Many OEMs push proprietary systems that lock businesses into their specific ecosystem, leading to long-term operational challenges such as high costs, limited flexibility, and difficulty integrating with other technologies or adapting to evolving needs. Fídus Global avoids this by providing solutions that are open, scalable, and adaptable.

Freedom in Upgrades and Maintenance

By allowing clients to seamlessly integrate new technologies without replacing entire systems, Pontem has saved businesses significant time and money by reducing costly downtime and avoiding the need for large-scale equipment overhauls.

Value Proposition

This approach reduces the total cost of ownership by eliminating vendor lock-in, giving clients the freedom to choose cost-effective solutions while maximizing operational autonomy and flexibility.

Features

Safety

Comprehensive safety assessments and compliance checks are conducted throughout the design and installation processes, ensuring that every aspect of the system minimizes risks to workers and operations, creating a safe and reliable work environment.

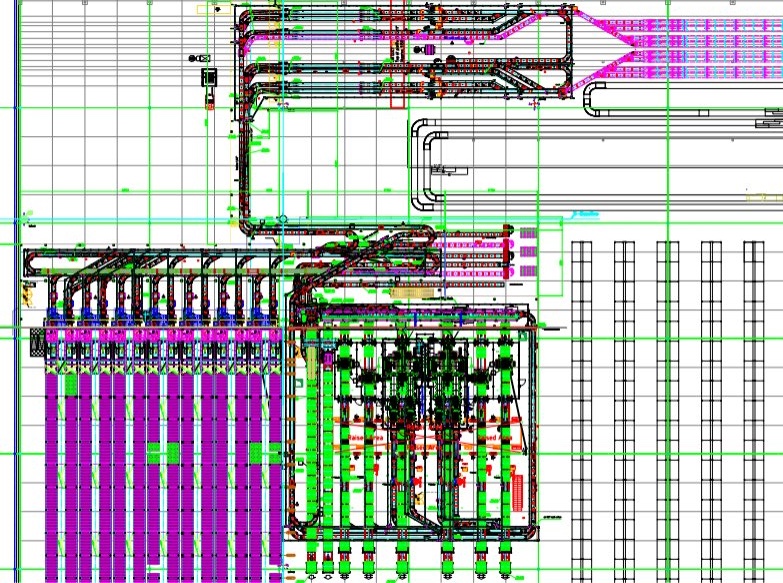

Layout Design / Ergonomics and System Flow Considerations

The goal is to create a warehouse environment that maximizes productivity and optimizes the movement of materials while minimizing strain on equipment and employees. This involves optimizing the arrangement of machinery, workstations, and equipment to ensure that the layout supports a smooth flow of tasks, reducing delays and bottlenecks. It also involves designing pathways for the efficient transport of goods, which minimizes handling times and reduces the risk of damage or loss.

Mechanical, Electrical, and Controls

Fídus Global ensures that warehouse and industrial systems are designed and implemented to meet international standards. Proper mechanical, electrical, and controls considerations are crucial for the reliable operation of automated systems.

WCS Software, SCADA, Alarms & Notifications, and Data Analytics & Reporting

Fídus Global integrates advanced WCS software, SCADA systems, alarms, notifications, and data analytics to enhance warehouse operations. Together, these elements create a cohesive and intelligent system that optimizes performance, reduces operational risks, and supports seamless, data-driven management of warehouse processes.

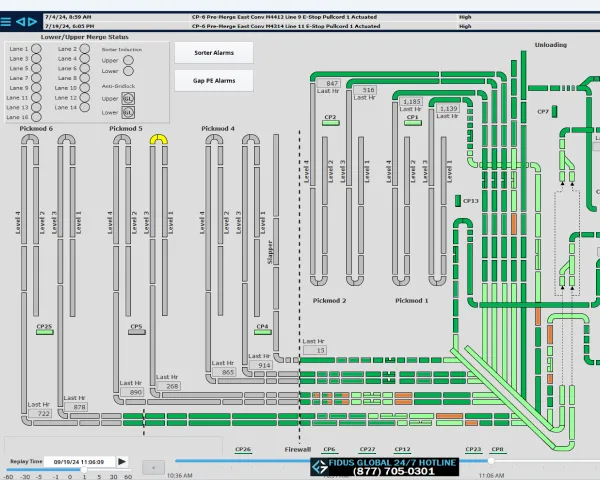

Flashback Function

The Plant Replay function within our SCADA system enables users to “rewind” the system’s history for up to a year (or longer based on storage capacity) to view past performance, identify root causes of issues, and compare historical and current operations, creating a robust flashback function that drives continuous improvement. By integrating historical data analysis into real-time feedback processes, this feature helps identify and address issues proactively, ensuring that systems remain adaptable, efficient, and responsive to evolving demands, ultimately enhancing productivity and performance.

Results

Increased and Improved Maintainability, Reliability, and Quality

Spare Parts Consistency

Improved management of Component Obsolescence

Open Architecture

Regulatory Compliance

Visibility/Transparency

System Enhanced

Data that Supports Operations

Global Specifications Detailed Overview

Fídus Global’s Global Specification service enables companies to regain control over their material handling systems, ensuring that they are not locked into restrictive and costly proprietary solutions from OEMs. This service promotes flexibility, reduces costs, and enhances the ability to support and evolve these systems over time.