Take Back Control of Your Warehouse Automation

Extend the life of your systems without starting over. Gain visibility, vendor choice, and a lower total cost of ownership.

Trusted By

Trusted By Teams At

.png?width=1200&length=1200&name=Media%20(1).png)

We Meet You Where You Are

Fidus supports every stage of your warehouse lifecycle with open systems, modular upgrades, and expert support. Whether you’re launching a new facility or updating legacy equipment, we can help.

Solutions that Keep You In Control

Automation Software

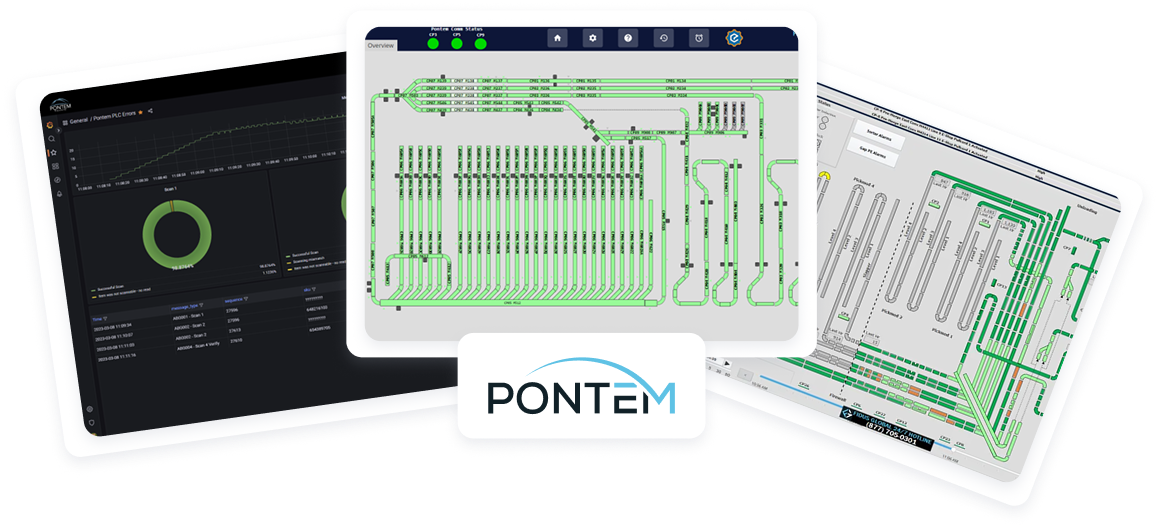

Pontem, our award-winning, open-architecture platform connects your WMS, equipment, and data giving you real-time visibility and full control.

Modernization Services

Controls, software, and hardware retrofits that extend system life and boost performance.

Maintenance & Field Services

Emergency response, preventive maintenance, and on-site techs ready when you need them.

Parts & Inventory Solutions

From legacy replacements to stocking programs, we keep your operations moving.

System Design & Engineering

Design, optimization, and integration built around your operation, not someone else's template.

Your Automation, Your Terms: Powered by Pontem

Our award-winning automation software connects your systems, controls, and data no matter your current vendor. Pontem gives you real-time visibility and the freedom to evolve on your terms, not theirs.

- Integrates with any hardware and software

- Modular, open architecture

- Real-time dashboards with Pontem View

- Flexible add-ons powered by Pontem Bolt

Real Customers. Real Results.

From 12 to 2 headcount via eSort

Right-sized sortation enabled faster inbound without overbuilding

$4.4M a year savings for Fortune 500 Retailer

Reduced dependency on OEMs and unlocked throughput gains with Pontem

72 hours vs. 3+ weeks. 100% inventory preserved

After a lightning strike disabled critical cooling towers, Fidus restored refrigeration in under 72 hours—avoiding weeks-long OEM delays, preventing product loss, and keeping outbound operations on track.

Audit in 24 hrs. Repairs in 72. Operations never stopped.

Fidus completed a full sorter audit and repairs in 72 hours, restoring stability with zero operational downtime and equipping the in-house team to prevent future disruptions.

Is Your Warehouse Tech Costing You?

Discover the 3 early warning signs that your legacy systems are creating hidden costs and inefficiencies.

Not Sure Where to Start?

Answer 5 quick questions to uncover the fastest ROI wins in your operation — no commitment, just clarity

You Don’t Have to Rip and Replace to Level Up

Modernize at your pace with flexible upgrades, transparent support, and modular solutions that grow with you.

.png)